Your advantage – maximum safety with package testing

To fulfil your wishes and demands – and the legal requirements for securing packages too – in our DUO LAB Technology Centre we provide comprehensive laboratory testing to develop package testing concepts for securing materials.

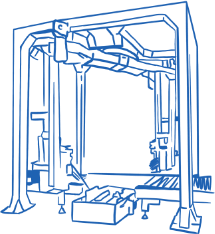

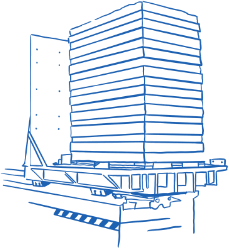

Our technology centre includes a state-of-the-art laboratory for this purpose, enabling us to undertake testing on entire unit loads. This unique packaging testing laboratory helps us come up with securement concepts for complete loads and transported products, and to perform testing on them. A systems analysis of the predominating transport conditions and environmental influences provides the basis for developing individually-adapted securement measures – from the primary packaging through to the entire unit load.

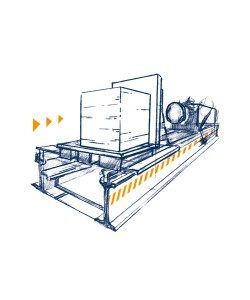

We’ll work with you to validate all the challenges of transport, and develop scientifically-based packaging testing, analyses and optimizations. Our testing focuses on your individual requirements for the packaged product, securing your unit load and the associated packaging process. By optimizing your transport process, we’ll help you make your transport cost-effective, safe and worry-free for everyone involved.

- Protect your products from external loads and influences

- Maximum unit load securement, thanks to development of individual package testing concepts

- Optimization of your consumption of materials

- Optimization of your packaging process and packaging design

- Internationally-recognized test reports and certificate